Installation and function of ceramic filter plate:

The efficiency of the foam ceramic filter board is closely related to the correct installation. At the same time, the reduction of inclusions in the process of operation, which is not necessary, such as ignoring smelting, heat treatment furnace, casting, etc. In order to prevent heavy pollution of pure aluminum after filtering.

When installing and using the ceramic filter plate, the ceramic foam filter supplier says that the following aspects should be paid attention to:

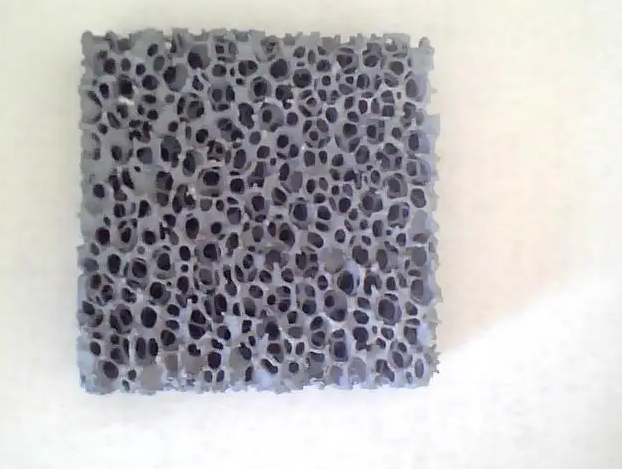

Correct selection of filter plate: The size and specifications of the filter plate must be considered in the selection of the number of holes for a specific type of metal filtration flow range, the maximum level, the total amount of filtration, and the factors of the cleanliness of the primary aluminum liquid.

Melt filtration pretreatment can not be ignored: such as furnace and holding furnace slag scraping normal, cleaning furnace; refining, and so on. In particular, the in-line degassing device is still necessary because it can not only reduce the hydrogen content in the melt, but also remove some of the non-metallic inclusions.

Melt filtration pretreatment can not be ignored: such as furnace and holding furnace slag scraping normal, cleaning furnace; refining, and so on. In particular, the in-line degassing device is still necessary because it can not only reduce the hydrogen content in the melt, but also remove some of the non-metallic inclusions.

The filter plate should be matched with the square elevated temperature filter box: it is suitable for sealing, which can prevent the metal from filtering from the notch into the box, and also avoid the foam filter plate being too light, aluminum water failed.

Preheating before use: Preheating removes moisture and facilitates initial instantaneous filtration. Preheating can be achieved by electric or gas heating. Under normal circumstances, about 15 minutes.

Normal filtration process, no slag, avoid knocking, vibration filter plate. At the same time, there should be full water to avoid groove aluminum, aluminum water too great movement.

After casting, drain the metal for cleaning and ceramic filtration plates. As a vibrator, mounted on the filter plate, one minute of vibration is removed from the retention of 75% of the liquid metal on the filter plate.

Finally, the ceramic filter plate is cleaned around, and then the filter plate is removed by coagulation.